Process Gas Compression, Blower & Vacuum Systems

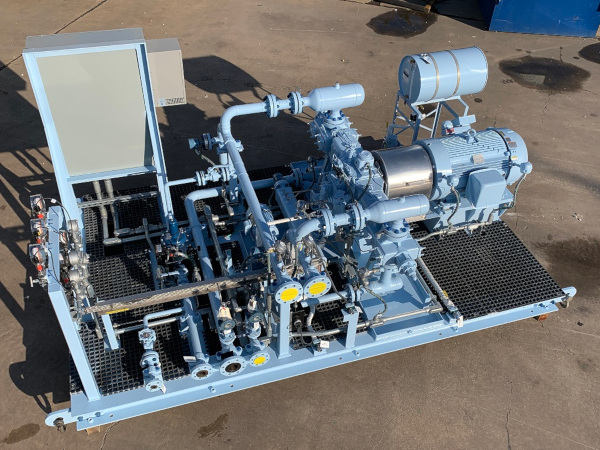

Fisher Energy Process Gas Compression Systems can be found in operation in power plants for natural gas fuel boosting, as sales gas compressors in biogas and landfill gas facilities, pressurizing vent gas for tank farm and unloading facilities, and in various specialized hydrocarbon and process gas applications in chemical and refining processes. Fisher utilizes rotary screw (lube and non-lube), sliding vane, and reciprocating (lube and non-lube) compressors, based on your specific application. These compressors are paired with our engineering know how on modularization and minimization of pulsations and vibrations, and coupled with subsystems for lubrication, acoustics, pressure control, separation, advanced controls and instrumentation, and noise and weather enclosures, dependent on the demands of each application. Fisher Energy maintains a keen focus through the design, fabrication, and start-up phases on operability and maintainability, providing compressor systems with the lowest cost of ownership in the industry.

Process Gas BlowersFisher Energy Process Gas Blower Systems are well known in the industry, and used by top tier customers in the chemical manufacturing, hydrocarbon and chemical logistics, landfill gas, biogas, and oil & gas markets worldwide. Fisher Energy utilizes both positive displacement and multi-stage blowers to meet the low pressure compression needs of our customer s gas handling needs, with both standard and highly customized systems.

Process Gas Vacuum SystemsFisher Energy Vacuum Systems are designed for industrial process vacuum applications including evaporation, stripping, distillation, evacuating, drying, and degassing. We offer both standard designs and highly customized vacuum systems, based on our customer s requirements and the specific needs for each application. Our experience with a large variety of vacuum systems, as well as our access to a wide range of technologies, allows us to specify the most efficient and cost-effective solution for your vacuum needs, including blowers, liquid ring pumps, ejectors, and sub-cooling equipment.